The powerful and accurate servo controlled speed and load control

Roller on roller features independently driven twin disc configuration offering rolling-sliding contacts with a wide range of contact pressures.

The roller on roller set up is widely accepted as a reliable precursor to FZG tests.

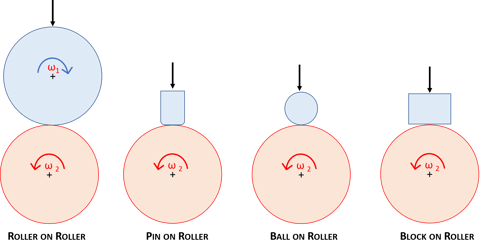

Being modular, multiple contact configurations like block on ring, ball on ring, conformal contacts are also possible, making it a truly multifunctional tribometer that can be used for evaluating materials and lubricants used in rolling element bearings, gears and rail-wheel applications.

Multifunctional system capable of changing the test configuration from line contact (roller on roller) to area (pin on roller or block on roller) or point (ball on roller) contact. Along with the ease of operation, it helps to achieve high throughput research.

The speed of each roller is controlled independently of each other using two servo motors. Therefore, variable slide to roll ratio (0 to 200%) can be achieved by setting different spindle speeds for two rollers. The motion direction can be set to clockwise or counterclockwise to simulate lubricant entrainment and reverse entrainment (starvation) conditions.

Friction torque is generated during the motion of the rollers in contact. This friction torque is acquired by a torque sensor. Linear displacement of the rollers due to creep and wear is measured using a linear variable differential transducer (LVDT) fixed to the stationary block on the top spindle assembly.

The twin disc tribometer comprised of two parallel spindles where each spindle is driven by a variable speed motor, automated loading unit, heating unit, friction torque sensor and linear wear sensor.

The servo controlled loading system provides a wide range of contact pressures and flexibility of continuous, ramped and custom load profiles.

The experiments can be conducted in lubricated or dry conditions. Temperature in the oil cup is managed using embedded heaters and temperature sensors. In the case of dry test conditions, a high temperature module is available as an option for higher temperatures.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10

Email: info@ducom.com